Базовая информация.

| Модель №. | 40-1 |

| Размер(Д*Ш*В) | 1350X1460X1800мм |

| Цвет | В соответствии с Вашим запросом |

| Масса | 1,1 т |

| Цикл формования | 40-е годы |

| Тип блока | Твердый блок, пустотелый блок, кирпич брусчатки |

| Кирпичный сырьё | Цемент, Песок, Щебень |

| Машинные материалы | Q235B |

| Размер поддона | 850*450*20 мм |

| Власть | 8,8 кВт |

| Транспортный пакет | Контейнер |

| Спецификация | КТ40-1 |

| Товарный знак | Шанман |

| Источник | Китай |

| Код ТН ВЭД | 8474802000 |

| Производственная мощность | 50000/год |

Описание продукта

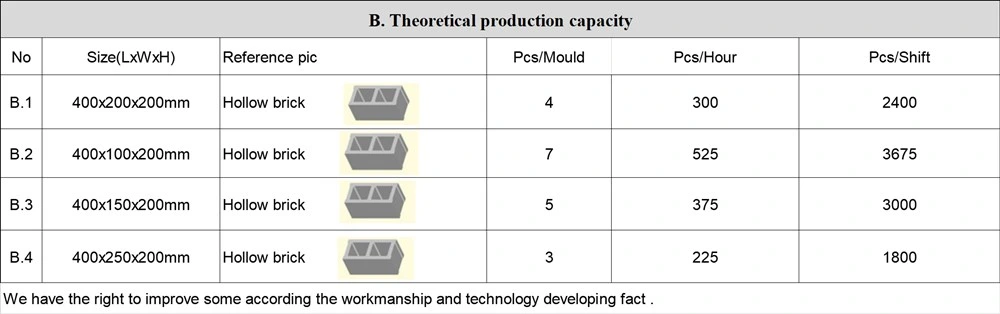

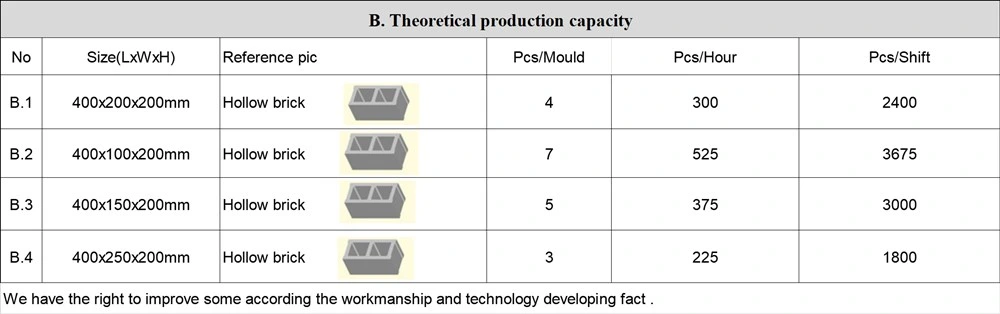

1. ОписаниеМашина для производства блоков QT40-1, которая может производить 4 полых блока размером 400*200*200 мм в каждой форме, производительность составляет около 2240-2880 шт/8 часов. Данная модель является хорошей машиной для начала собственного бизнеса. Небольшие инвестиции, быстрая окупаемость.Он работает с вибрационным давлением для производства различных полых блоков, полнотелого кирпича, кирпичей с переплетением, бордюров и т. д. только путем замены различных форм.

2. Технический

| Основной технический параметр |

| 1 | Размер хост-машины | 1350х1460х1800мм | 6 | Мощность хост-машины | 8,8 кВт |

| 2 | Вес хост-машины | |

| |

| |

| | | |

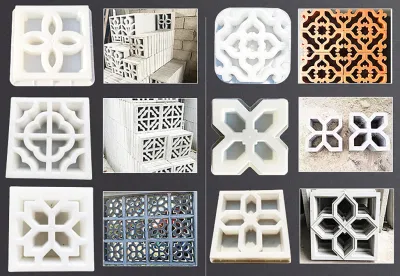

Various styles of brick machine mold, you can choose According to customer requirements, we can customize all kinds of brick machine molds, Hollow brick mold size: 390 * 190 * 190,390 * 180 * 190,390 * 240 * 190,390 * 190 * 90 standard brick mold size: 240 * 115 * 53,240 * 115 * 50,240 * 115 * 49, 240 * 115 * 51.7. Raw material can be used for making bricks:It uses sand, gravel and cement as raw material, and can be added with fly ash, slag, steel slag,coal gangue,perlite and other industrial refuse.This is the most popular proportion in making block making machine:1. Standard concrete block: Cement 9-12%, sand 40%, stone 45%, water 3%2. Light concrete block: Cement 9-12%, slag 80-90%, water 3%3. Cement 9-12%, sand 10-20%, stone 30-40%, slag 25-50%, water 3%4. Cement 8%-10%, sand 30%-40%, stone 50%-60%5. Cement 8%, sand 60%, Fly ash 30%, gypsum 2%.8. In order to save your valuable time, please kindly add information as following:1.The exact size of blocks and bricks you need;2.Picture of your blocks;3.Industrial electricity voltage.(volts & Hz)4.The specific price please refer to your needs, such as details list.Note: If you want more such as shipping cost, machine video, catalog, details photos and so on, please tell us, we will do the best to help you.9. Our Services Pre-sales Service (1) Professional suggestions (raw material matching, machine selection, the condition of building factory,feasibility analysis for brick machine production line)(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick)(3) 24 hours on-line service(4) Welcome to visit our factory and production line anytime.(5) Introduce the company file, product categories and production process.(6)Sample testing support. Sale(1) Update the production scheduling in time(2) Quality supervision(3) Product acceptance(4) Shipping on time After-sale(1) Training how to instal the machine, training how to use the machine. (2) Engineers available to service machinery overseas.(3) Recall clients regularly ,get feedback in time,keep well communication with each other(4) One year guarantee10. Shipping and delivery11. Questions you may have?1. What is the Raw Material of Block Making Machine?Our Equipment is Concrete Block Making Machine.The Raw Materials of Concrete are Water, Cement, Sand, Stone Powder, Fly Ash, Slag etc..2. Which one Block Making Machine is more suitable for me?The Models of our Block Making Machine are QT10-15,QT8-15,QT4-15,QT4-185,QT4-24,QT4-26,QT40-,QT40-2each model has different Configuration.Our company also owns 10-15 Concrete Block Making Machine and 6-30 Mobile Concrete Block Making Machine.Which one of machines is right for me?The following questions should be carefully considered by yourself.Firstly,what Block Size do you want make?How many Blocks do you want make per day?What is your budget for this block machine projectWe can choose the suitable model and configuration for you if above information can be provided.3. How could we buy machine from us?Our company will sign Sales Contract or Proforma Invoice with you by Email,Fax or Mail after confirming the Equipment that you want to buy; or we can make invioce on made in china plate form our company will arrange Equipment and Mould Production after receiving your 30% deposit.The balance should be paid when the production is finished.Then we will arrange delivery to your closest Sea Port where you can take over the Equipment.4. How could we take over the Equipment?At present our customers come across more than Eighty Countries around the world.They are using our machine,but most of our machine spread in Africa,Middle East,Southeast Asia, Eastern Europe and South America.We will book the Container from the Ship Company when the production is finished.Then the truck will take the Container to our factory for loading,be back to port after finish loading.The Ship Company will transport the Container to designated port where the customers can take over the machine.We also can be responsible for transporting the Equipment to Inland City,but according to our previous experiences,it will be saving transport costs if customers can cover the Inland Transport by yourself.